Validation of an industrial process to manufacture isosorbide bis(methyl carbonate) at pilot level

This project has received funding from the Bio Based Industries Joint Undertaking (JI) under the European Union´s Horizon 2020 research and innovation programme under grant agreement N0 790440. The JU receives support from the European Union´s Horizon 2020 research and innovation programme and the Bio Based Industries Consortium

VIPRISCAR

The Project

Isosorbide (IS) is still a low market volume bio-based chemical but with a high Cumulative Annual Growing Rate of 10.9%. The use of isosorbide (IS) in the manufacturing of intermediate building blocks and high volume polymers, such as polycarbonates, has some drawbacks that could be overcome by using isosorbide bis(methyl carbonate) (IBMC), a barely explored IS secondary building block which is proposed to enhance IS value chain. VIPRISCAR will validate a highly-efficient IBMC production process in an industrially relevant environment (TRL 5) able to be up-scaled and produce, under suitable market conditions, IBMC at a similar price to that of current oil-based monomers used in polycarbonates and polyurethanes. The project will show also a proof of principle for the added value IBMC brings to the market by demonstrating the usefulness of polymers derived thereof in three high-volume market sectors: industrial coatings, hot-melt adhesives, and biomedicine (antithrombotic-antimicrobial catheters).

Acronym: VIPRISCAR

Call: H2020-BBI-JTI-2017

Topic: Novel secondary bio-based chemicals without significant fossil-based counterparts but with high application potential

Type of action: Research & Innovation Action

Value Chain: Across VCs

Start date: 01 June 2018

End date: 31 May 2021

BBI JU contribution: 2,8 M€

Project coordinator: TECNALIA Research & Innovation

Objectives

- Move the production process from the proof of concept (TRL 3) to a validation in laboratory environment (TRL 4).

- Validate isosorbide bis(methyl carbonate) (IBMC) production process in a relevant industrial environment (TRL 5).

- Develop polyurethane dispersions (PUDs) based on IBMC-derived materials.

- Assess coatings prepared from PUDs.

- Develop and assess nitrogen-containing IBMC derivatives for use in non isocianate polyurethane (NIPU) coatings.

- Develop IBMC-based NIPUs dispersions for use as adhesives.

- Develop IBMC based polycarbonate polyols for use as adhesives.

- Develop catheters with antibacterial and antithrombotic properties using IBMC-based NIPU.

- Confirm that the isosorbide derivates and the final products meet the toxicology requirements of REACH.

Expected impacts

VIPRISPAR will contribute to the overall Bio Based Industries Joint Undertaking goals through

Move the production process from the proof of concept (TRL 3) to a validation in laboratory environment (TRL 4)

Validate isosorbide bis(methyl carbonate) (IBMC) production process in a relevant industrial environment (TRL 5)

Develop polyurethane dispersions (PUDs) based on IBMC-derived materials

Consortium

External advisory board

Alan Patrick Giles.

Mr. Giles is a Founding partner, Rawlings Giles, attorneys and solicitors with office in London, Paris and Brussels. He has an MBA and JD degrees from American universities and has spent his career advising companies engaged in international joint ventures from and office in London.

Robert Kirschbaum.

SakuragiConsult founder. 35 years with DSM fostering diverse innovations and from 1997 in charge of the DSM New Business Development Corporation, being until 2009 Vice President of Innovation. Since January 2015 he also acts as Senior Advisor to the Chief Technology Officer of Royal DSM. Giulio Natta Award (May 2010). Visiting lecturer on Corporate Venturing and Entrepreneurship at the ESADE (Barcelona) Business School and the Erasmus University/RSM (Rotterdam).

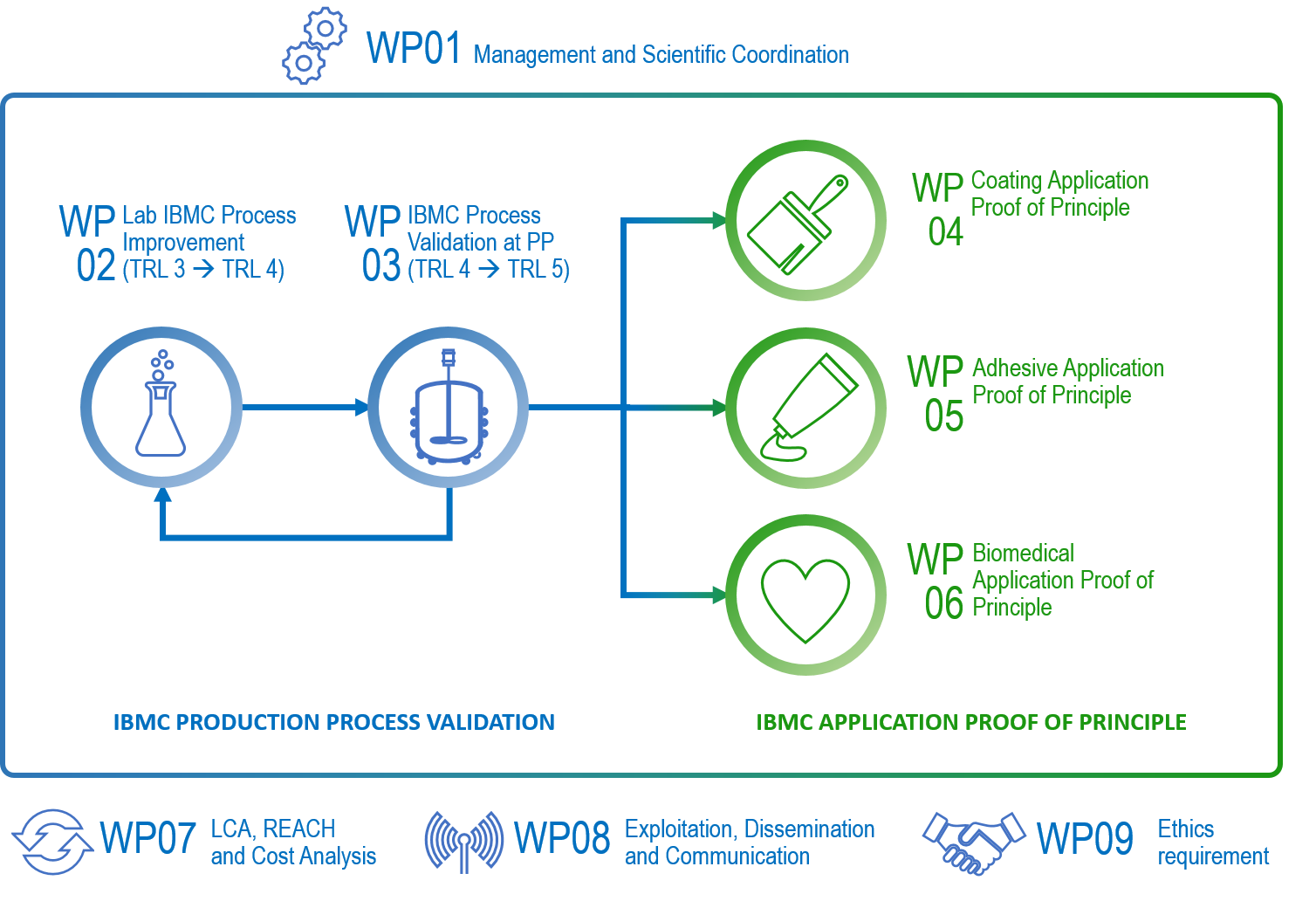

Project Structure

WP1 – Management and scientific coordination

More Info

This Work Package considers the overall management, communication and coordination between the different partners, as well as the monitoring of the scientific and technical progress of the entire project, by means of the supervision of the achieved milestones, the management of the risks and establishment of contingency plans, gender equity, and other nontechnical aspects. It also provides outputs for knowledge management and other RTD innovation related activities, such as Intellectual Property Rights and dissemination.

Task

- Project coordination and quality assurance

- Communication, reporting and monitoring

WP2 - IBMC process development and validation at lab scale

More Info

The objective of this WP is to develop an Isosorbide bis(methyl carbonate) (IBMC) manufacturing process at lab scale moving from the current TRL 3 to 4, obtaining the needed data to scale-up the process till TRL5 in WP3.

Task

- Reaction improvement

- Separation and purification procedure

- Pre-up-scaling

- Process design and integration

- Process simulation and preliminary up-scaling

WP3 - IBMC process validation at pilot plant

More Info

The objective is to validate an IBMC manufacturing process at pilot plant (TRL5).

And to obtain data for detailed LCA and cost analysis including bill-of-materials and energy consumption.

Tasks

- Intermediate scaling-up

- Pilot plant design

- Pilot plant starting

- Pilot plant operation

- Plant up-scaling simulation to industrial scale

WP4 Coating application proof of principle

More Info

Wp4 is devoted to develop potential formulations (at TRL 3) from IBMC-derived polymers as a proof-of principle of polyurethanes coatings with competitive performance vs. market requirements.

The objectives are:

- To develop polyurethane dispersions (PUDs) with oligocarbonates-diols from IBMC for PU coatings.

- To develop non-isocyanate polyurethanes (NIPUs) for PU coatings.

To develop waterborne PU coatings and NIPUs coatings as a proof-of-principle demonstration for derived IBMC functional oligocarbonates in future greener market applications

Tasks

- Waterborne polyurethane dispersions (PUDs) for coatings.

- IBMC based NIPUs for coatings.

- Coatings formulation and testing of properties

WP5 Adhesives application proof of principle

More Info

The objectives of this WP are:

- To develop Poly(carbonate-ester)-diol adhesives from IBMC and commercial polyester-diols as a proof of principle demonstration o for IBMC in future greener market applications.

- To develop NIPUs dispersions useful as adhesives from IBMC and commercial polyamines as a proof of principle demonstration o for IBMC in future greener market applications.

Tasks

- Adhesives based on IBMC and commercial polyester/polyether polyols.

- NIPUs-based adhesives

- Adhesives formulation and testing of propertiesnary up-scaling

WP6 Bifunctional catheters application proof of principle

More Info

The objectives of WP6 are:

- To manufacture a proof of concept laboratory prototype of a new bio-functional (antithrombotic-antimicrobial) catheter based on an IBMC-derived NIPU, such catheter should exhibit general functional static and dynamic characteristics comparable with those of commercially available catheters.

- To obtain 1 thermoplastic IBMC-based biofuncionalized NIPU

- To confirm the biocompatibility and biofunctionality of final prototype

Tasks

- Synthesis of bio-functionalized thermoplastic IBMC-based NIPUs.

- Processing of bio-functional IBMC-based NIPU into a catheter

- Assessment of Biocompatibility and biofunctionality of the final prototype

WP7 LCA, Reach and cost analysis

More Info

This WP will validate the VIPRISCAR technology and its technical performance, economic feasibility, and to ensure the future deployment at industrial level. It will demonstrate the sustainability and business potential of the novel IBMC-based products in respect to the state-of-the-art and existing technologies.

WP7 will also identify barriers, limitations, regulatory/legislation aspects, and product safety issues, including the REACH regulation, which could affect the market entrance and exploitation of VIPRISCAR products and to define the Key Performance Indicators (KPIs) of the VIPRISCAR technology.

Tasks

- Technical evaluation of VIPRISCAR concepts

- Economic validation: Life cycle cost analysis (LCC) and economic feasibility

- Environmental feasibility study including life cycle assessment (LCA)

- Health and safety study (HSS)

- Definition of European and local legal and non-legal limitations, barriers and standards

WP8 Exploitation, Dissemination and Communication

More Info

The objectives of this Work Package are:

- To ensure exploitation of results, including handling of Intellectual Property Rigths (IPR) issues.

- To ensure efficient management of project data.

- To define the business models and plans, including the relevant market analyses.

- To ensure widespread dissemination of VIPRISCAR results to public, academia and industry.

- To communicate with all stakeholders on VIPRISCAR project specific issues and results.

Tasks

- Market intelligence and competitive analysis

- Business models and financial impacts

- Exploitation Plan

- IPR and Exploitation Risk Management

- Development of the Project communication and dissemination strategy

WP9 Ethics requirement

Publications

News

Bright outlook for VIPRISCAR

As VIPRISCAR comes to a close, B4Plastics shows this May 21th the outcomes and future for the production of novel sugar-based polymers, in particular the ones derived from IBMC, a bio-based monomer that can be obtained by the company at a...

An on-line workshop from VIPRISCAR to reinforce BIOECONOMY in Europe

The VIPRISCAR Project completed three years of intensive research in the generation of new solutions for a Bioeconomy approach with the dissemination of a free access webinar. Towards a sustainable chemical model in Europe (18th May 2021) was a specific online...

The VIPRISCAR project arrives to the students

It has become a tradition that B4Plastics is introduced to young students of 18 in Belgium, that make up their mind to choose their high school education. In this year’s event (2021.02.02), “a job in the bio-economy” is reflected in an attractive way by B4Plastics’...

The economic potential of IBMC in Europe in a near future is presented by Tecnalia in the Open Acces Government.

Tecnalia analyses the opportunities of the new biomass-derived building block IBMC that is studied in the VIPRISCAR project into the new Bioconomy and Circular strategy that Europe intends to introduce as a prevailing development model. More information: "Isosorbide...

A successfull presentation of the VIPRISCAR project in the XIV. INTERNATIONAL RESEARCH CONFERENCE ON BIOPRODUCTS ENGINEERING AND BIOPROCESSING

TECNALIA has received the certificate OF BEST PRESENTATION AWARD in the XIV. INTERNATIONAL RESEARCH CONFERENCE ON BIOPRODUCTS ENGINEERING AND BIOPROCESSING (ICBEP 2020) entitled Isosorbide Bis-Methyl Carbonate: Opportunities for an Industrial Model Based...

The VIPRISCAR Project develops ecologic polyurethane dispersions from IBMC. Results presented in the Online IMAGINENANO congress 29 Sept-01 Oct 2020

Aqueous polymeric nanodispersions are an alternative to reduce volatile organic compounds emissions in coatings and adhesive products. However, the industrial fabrication process requires an organic solvent to reduce the viscosity during IBMC prepolymer synthesis....

Events

2021 · July, 18 · Frontiers of Polymer Colloids From Synthesis to Macro-Scale and Nano-Scale Applications

Date: July 18, 2021

Place: Prague – Czech Republic

Link to the event information

2021 · Sept, 14-16 · European Coatings Show

Date: September 14-16, 2021

Place: Nuremberg – Germany

Link to the event information

Contact

Project Manager

Dr. Soraya Prieto Fernández

Technical coordinator

Dr. Olga Gómez de Miranda

This project has received funding from the Bio Based Industries Joint Undertaking (JU) under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 790440. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Bio Based Industries Consortium